Electrodes

Electrodes represent the metal structures that extract current from the solar cell. Their definition includes both the geometry of the metal elements and the properties of the contact interfaces between the electrodes and the underlying substrates.

Electrodes can be defined on the front and rear surfaces of the main absorber, which is typically the silicon wafer on which the solar cell is fabricated.

Changes to the electrode definition influence both series resistance and optical loss metrics reported in SunSolve Power, so the impact of these settings is visible in the electrical and optical output parameters.

Configuration and grid elements

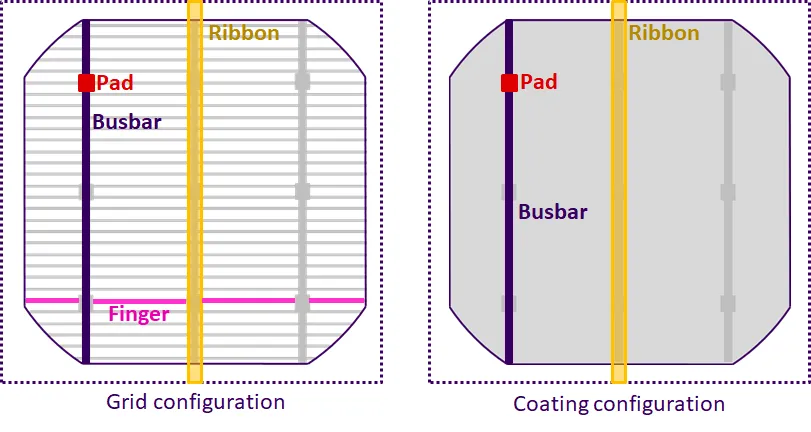

Section titled “Configuration and grid elements”A metal electrode can be defined on both the front and rear side of the “solar cell” layer. There are three possible layouts for each electrode: (1) grid, (2) coating and (3) none. When activated, the electrodes will be included in both the optical and electrical calculations.

The Grid electrode represents the standard H-bar design for a solar cell electrode. It is made up of a set of fingers arranged at right angles to a series of busbars. Both fingers and busbars run the full extent of the substrate (i.e. to the edge of the wafer). This configuration would typically be used for the front electrode of a standard or PERC solar cell and for the rear electrode of bi-facial cells. Note that SunSolve allows the user to set either the number of fingers and/or busbars to zero, effectively removing that element from the grid design.

The Coating electrode represents a surface covered entirely by an electrode. It is made up of a series of busbars with a continuous layer of metal between each one. This configuration would typically be used to simulate the rear side of a standard screen print or PERC solar cell. Note that the coatings are applied all the way to the edge of the wafer and it is not possible to define a gap at the edge.

All configurations allow the definition of cell interconnection ribbons (sometimes called ‘tabbing’). Ribbons are aligned to the same axis as the busbars. The length of the ribbon is the same as the extent of he unit cell (i.e. the wafer size + any surrounding area). Ribbons are applied to both the front and rear of the solar cell. In regular solar cells, there is one ribbon above each busbar, but in SunSolve it is possible to have any number of busbars or ribbons.

Note that the electrodes also contain pads (e.g. solder points between ribbons and busbars) as described in the grid calculator. The inputs to the pads affects the electrical calculation (i.e., the grid resistance) but they do not affect the optical calculations. As far as the optics is concerned, the pads are the same width and material as the busbars.

Cross-sections of the grid elements

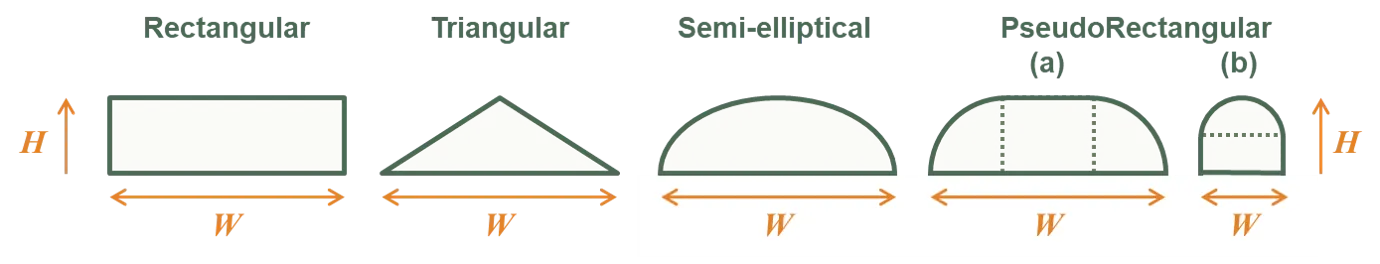

Section titled “Cross-sections of the grid elements”Four cross-sectional profiles are permitted for the fingers. Their dimensions are defined in the figure below. The fourth cross section, labelled “PseudoRectangular”, is recommended for simulations of typical screen printed fingers. It is defined as two quatercircles and a rectangle, and it has two variants: (a) wide, when , and (b) narrow, when . It is semicircular when .

SunSolve forces the cross-sectional profile of busbars to be rectangular.

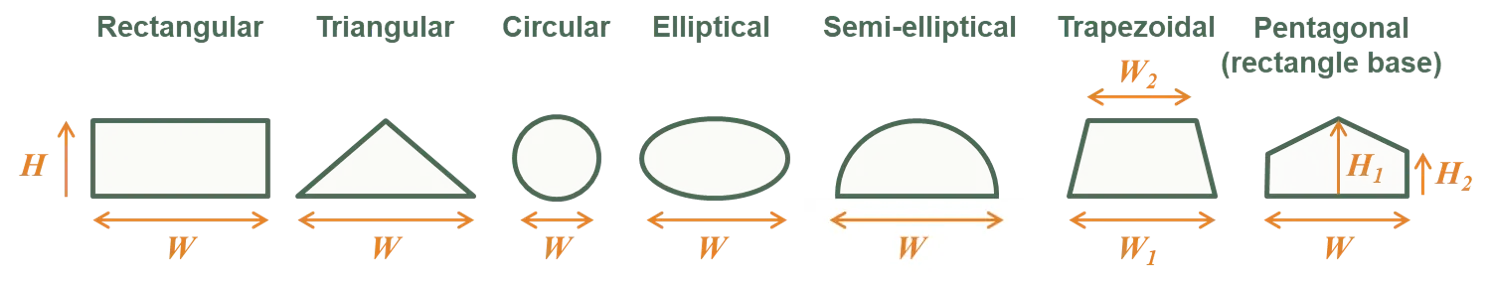

Eight cross-sectional profiles are permitted for the ribbons. The dimensions of seven of those are defined in the figure below. The rectangular ribbons can be textured, where the texture is on the side facing away from the solar cell.

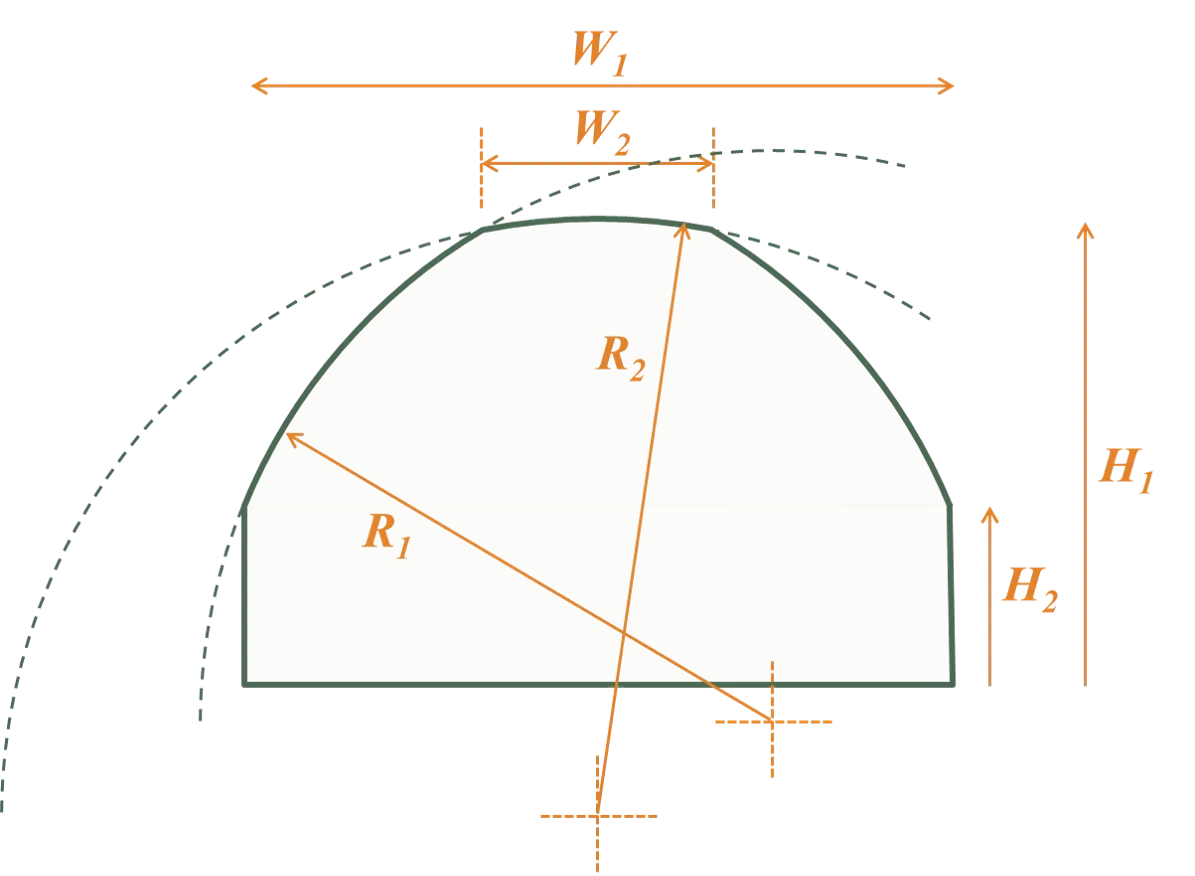

The final cross-sectional profile permitted for ribbons is called a “triple-arc” profile. It’s defined by six inputs and hence requires a larger image:

All of the above images show the cross-section of fingers and ribbons on the front of the solar cell. Turn the images upside to view the cross-section of fingers and ribbons on the bottom of the solar cell. E.g., the flat side of the semi-elliptical ribbons always faces the solar cell.

Contacts

Section titled “Contacts”The contacts of a solar cell constitute the regions where the electrodes make electrical connection to the substrate.

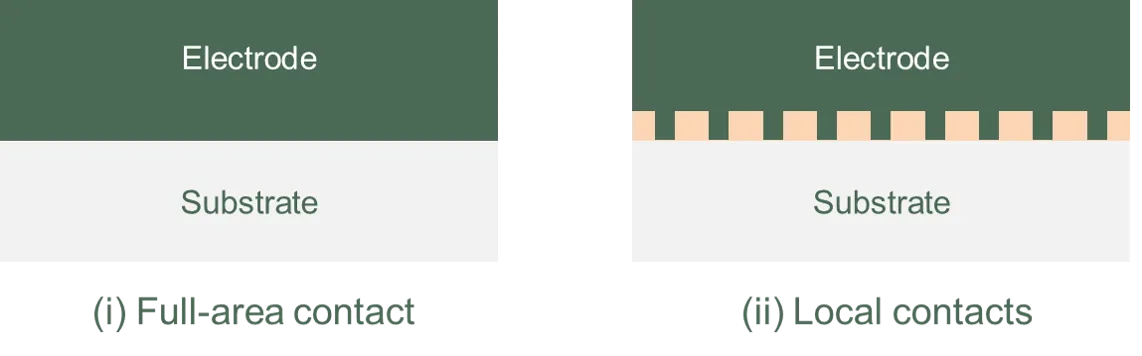

In some cells, like conventional screen-printed solar cells, the contact represents the entire interface between an electrode and the substrate (a full-area contact); in others, like PERC solar cells, the contact only occurs at certain locations under the electrode (local contacts).

The figures below show example cross-sections of an electrode with (i) a full-area contact and (ii) local contacts.

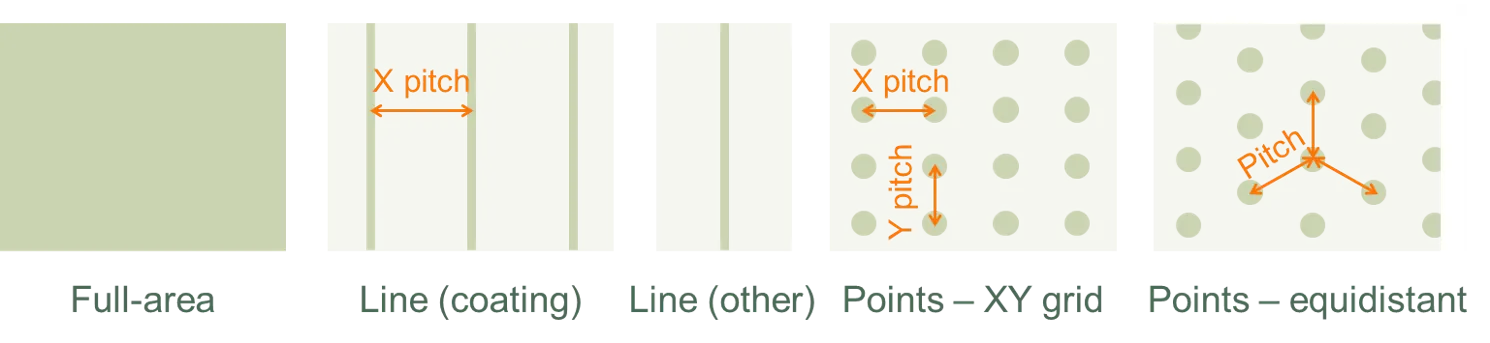

SunSolve permits several contact patterns. A contact pattern can be a ‘full-area’ pattern or it can be comprised of lines or points.

When a line pattern is selected, it represents periodic lines for coatings but a single central line for fingers or busbars. When a point pattern is selected, the points can be either circular or rectangular, and they can be laid in either an XY grid or an equidistant pattern. The figures below illustrate the various contact patterns.

In SunSolve, the contact patterns affect the optical behaviour of the solar cell but not the electrical resistance of the metal electrodes. To account for current crowding at the contacts, increase the value of the series resistance accordingly.

Optical properties

Section titled “Optical properties”The optical properties of the electrodes and their interfaces can be defined for each individual element (finger, busbar, coating). These properties affect the ray tracing but have no impact on the resistance calculations.

The optical inputs for the contacts can be found by either clicking on the front or rear surface of the solar cell on the “Layers” tab, or by clicking on “Define front/rear electrode” on the “Electrodes” tab.

Optical material The optical material sets the refractive index, n(λ) & k(λ), of the electrode element. This material can be selected from a library of materials whose n(λ) & k(λ) have been published, or customised values of n(λ) & k(λ) can be uploaded.

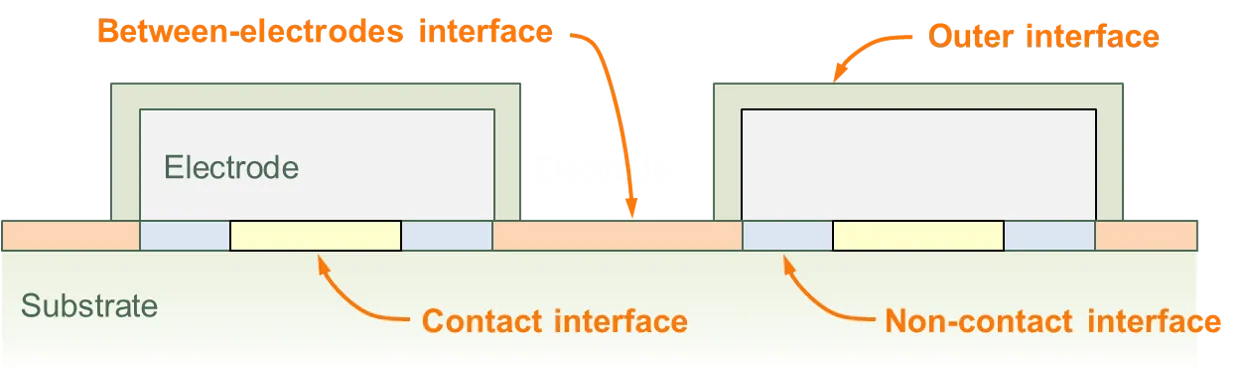

Electrode interfaces The optical properties of each electrode element (finger, busbar, coating) are also defined. There are either two or three interfaces:

- an outer interface, which faces away from the substrate of the solar cells,

- a contact interface, which defines the contact region between the electrode and the cell, and

- a non-contact interface, which defines the regions between the electrode and the substrate that are not in electrical contact (irrelevant for full-area contact patterns).

For finger and busbar electrodes (but not coating electrodes), the user also defines the substrate’s interface that lies between the electrodes.

The figure below illustrates the various interfaces associated with a substrate surface and electrode.

For each interface, the user defines

- scattering properties, and

- whether the user defines the reflectance, absorptance and transmittance (RAT) at the interface, or whether SunSolve calculates it using Fresnel and thin-film equations and the optical properties of the element’s material and thin-film stack.

The interfaces for ribbons are defined similarly except that (i) the surface facing away from the cell can be textured, and (ii) the same interface is applied to all sides of the ribbon.

Here are two examples of how the electrode and substrate interfaces might be assigned to represent common solar cells.

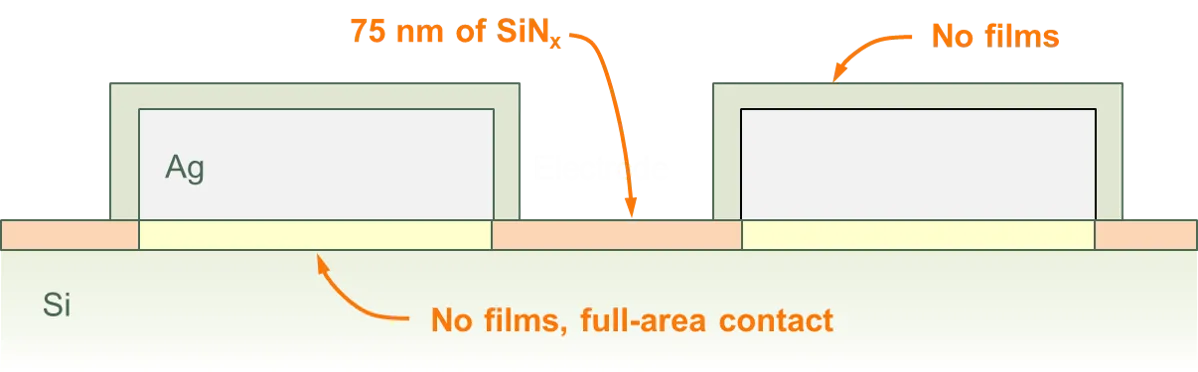

Example 1: Front-surface of a screen-printed solar cell

The front surface might be defined as having a grid of Ag, where there are no films under the electrodes but where SiNₓ lies between the fingers. Although it is not shown, the surface of the substrate would normally be textured with upright pyramids.

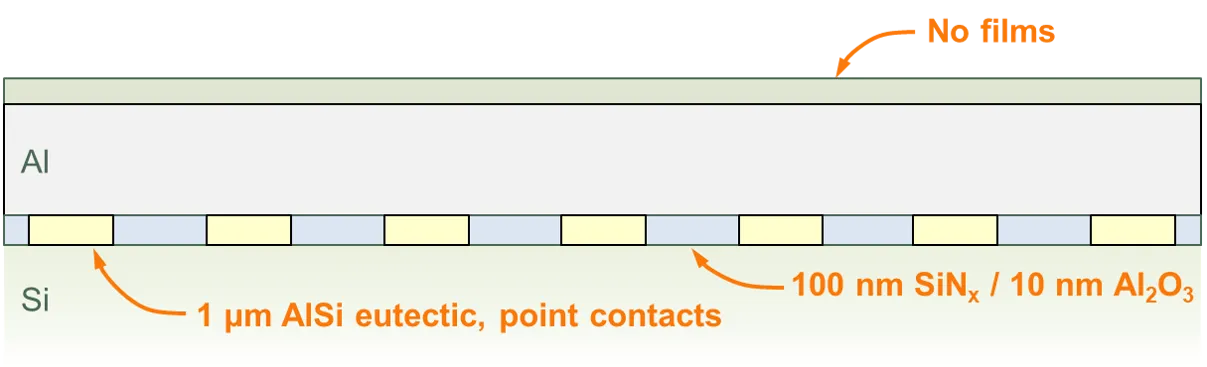

Example 2: Rear-surface of a PERC solar cell

The rear surface might be defined as having a coating of Al, where the Al is separated from the substrate by a film stack of SiNₓ on Al₂O₃ except at the point contacts where the interface is comprised of a thin film of AlSi euctectic.

Electrical properties

Section titled “Electrical properties”For each element the user can also define the electrical properties, including the metal resistivity and the electrode resistivity. These values are only used in the calculation of the grid electrical resistance and have no impact on the optical performance.